Coal Age Magazine - For more than 100 years, Coal Age has been the magazine that readers can trust for guidance and insight on this important industry.

Issue link: https://coal.epubxp.com/i/1009142

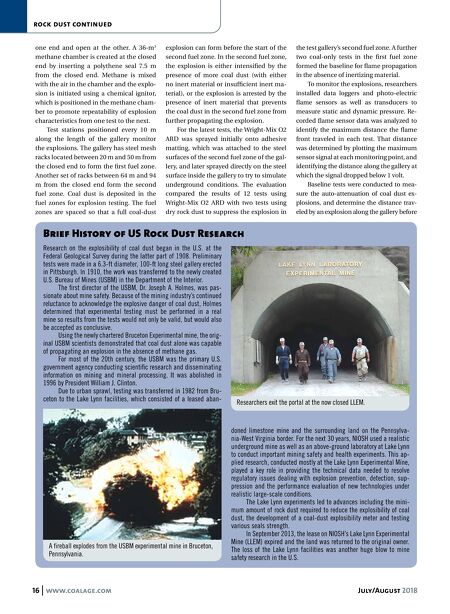

16 www.coalage.com July/August 2018 rock dust continued one end and open at the other. A 36-m 3 methane chamber is created at the closed end by inserting a polythene seal 7.5 m from the closed end. Methane is mixed with the air in the chamber and the explo- sion is initiated using a chemical ignitor, which is positioned in the methane cham- ber to promote repeatability of explosion characteristics from one test to the next. Test stations positioned every 10 m along the length of the gallery monitor the explosions. The gallery has steel mesh racks located between 20 m and 50 m from the closed end to form the first fuel zone. Another set of racks between 64 m and 94 m from the closed end form the second fuel zone. Coal dust is deposited in the fuel zones for explosion testing. The fuel zones are spaced so that a full coal-dust explosion can form before the start of the second fuel zone. In the second fuel zone, the explosion is either intensified by the presence of more coal dust (with either no inert material or insufficient inert ma- terial), or the explosion is arrested by the presence of inert material that prevents the coal dust in the second fuel zone from further propagating the explosion. For the latest tests, the Wright-Mix O2 ARD was sprayed initially onto adhesive matting, which was attached to the steel surfaces of the second fuel zone of the gal- lery, and later sprayed directly on the steel surface inside the gallery to try to simulate underground conditions. The evaluation compared the results of 12 tests using Wright-Mix O2 ARD with two tests using dry rock dust to suppress the explosion in the test gallery's second fuel zone. A further two coal-only tests in the first fuel zone formed the baseline for flame propagation in the absence of inertizing material. To monitor the explosions, researchers installed data loggers and photo-electric flame sensors as well as transducers to measure static and dynamic pressure. Re- corded flame sensor data was analyzed to identify the maximum distance the flame front traveled in each test. That distance was determined by plotting the maximum sensor signal at each monitoring point, and identifying the distance along the gallery at which the signal dropped below 1 volt. Baseline tests were conducted to mea- sure the auto-attenuation of coal dust ex- plosions, and determine the distance trav- eled by an explosion along the gallery before Brief History of US Rock Dust Research Research on the explosibility of coal dust began in the U.S. at the Federal Geological Survey during the latter part of 1908. Preliminary tests were made in a 6.3-ft diameter, 100-ft long steel gallery erected in Pittsburgh. In 1910, the work was transferred to the newly created U.S. Bureau of Mines (USBM) in the Department of the Interior. The first director of the USBM, Dr. Joseph A. Holmes, was pas- sionate about mine safety. Because of the mining industry's continued reluctance to acknowledge the explosive danger of coal dust, Holmes determined that experimental testing must be performed in a real mine so results from the tests would not only be valid, but would also be accepted as conclusive. Using the newly chartered Bruceton Experimental mine, the orig- inal USBM scientists demonstrated that coal dust alone was capable of propagating an explosion in the absence of methane gas. For most of the 20th century, the USBM was the primary U.S. government agency conducting scientific research and disseminating information on mining and mineral processing. It was abolished in 1996 by President William J. Clinton. Due to urban sprawl, testing was transferred in 1982 from Bru- ceton to the Lake Lynn facilities, which consisted of a leased aban- doned limestone mine and the surrounding land on the Pennsylva- nia-West Virginia border. For the next 30 years, NIOSH used a realistic underground mine as well as an above-ground laboratory at Lake Lynn to conduct important mining safety and health experiments. This ap- plied research, conducted mostly at the Lake Lynn Experimental Mine, played a key role in providing the technical data needed to resolve regulatory issues dealing with explosion prevention, detection, sup- pression and the performance evaluation of new technologies under realistic large-scale conditions. The Lake Lynn experiments led to advances including the mini- mum amount of rock dust required to reduce the explosibility of coal dust, the development of a coal-dust explosibility meter and testing various seals strength. In September 2013, the lease on NIOSH's Lake Lynn Experimental Mine (LLEM) expired and the land was returned to the original owner. The loss of the Lake Lynn facilities was another huge blow to mine safety research in the U.S. A fireball explodes from the USBM experimental mine in Bruceton, Pennsylvania. Researchers exit the portal at the now closed LLEM.