Coal Age Magazine - For more than 100 years, Coal Age has been the magazine that readers can trust for guidance and insight on this important industry.

Issue link: https://coal.epubxp.com/i/1055558

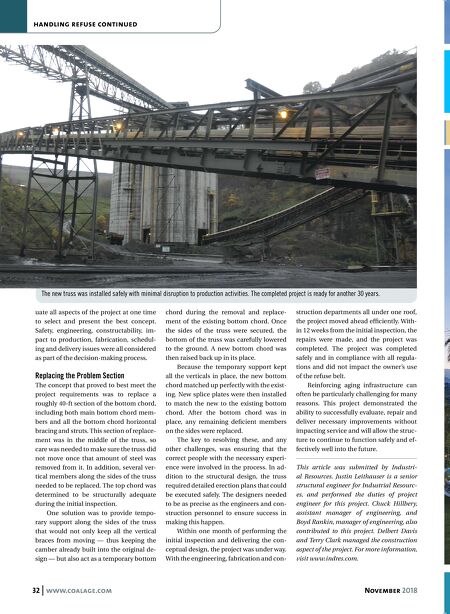

32 www.coalage.com November 2018 handling refuse continued uate all aspects of the project at one time to select and present the best concept. Safety, engineering, constructability, im- pact to production, fabrication, schedul- ing and delivery issues were all considered as part of the decision-making process. Replacing the Problem Section The concept that proved to best meet the project requirements was to replace a roughly 40-ft section of the bottom chord, including both main bottom chord mem- bers and all the bottom chord horizontal bracing and struts. This section of replace- ment was in the middle of the truss, so care was needed to make sure the truss did not move once that amount of steel was removed from it. In addition, several ver- tical members along the sides of the truss needed to be replaced. The top chord was determined to be structurally adequate during the initial inspection. One solution was to provide tempo- rary support along the sides of the truss that would not only keep all the vertical braces from moving — thus keeping the camber already built into the original de- sign — but also act as a temporary bottom chord during the removal and replace- ment of the existing bottom chord. Once the sides of the truss were secured, the bottom of the truss was carefully lowered to the ground. A new bottom chord was then raised back up in its place. Because the temporary support kept all the verticals in place, the new bottom chord matched up perfectly with the exist- ing. New splice plates were then installed to match the new to the existing bottom chord. After the bottom chord was in place, any remaining deficient members on the sides were replaced. The key to resolving these, and any other challenges, was ensuring that the correct people with the necessary experi- ence were involved in the process. In ad- dition to the structural design, the truss required detailed erection plans that could be executed safely. The designers needed to be as precise as the engineers and con- struction personnel to ensure success in making this happen. Within one month of performing the initial inspection and delivering the con- ceptual design, the project was under way. With the engineering, fabrication and con- struction departments all under one roof, the project moved ahead efficiently. With- in 12 weeks from the initial inspection, the repairs were made, and the project was completed. The project was completed safely and in compliance with all regula- tions and did not impact the owner's use of the refuse belt. Reinforcing aging infrastructure can often be particularly challenging for many reasons. This project demonstrated the ability to successfully evaluate, repair and deliver necessary improvements without impacting service and will allow the struc- ture to continue to function safely and ef- fectively well into the future. This article was submitted by Industri- al Resources. Justin Leithauser is a senior structural engineer for Industrial Resourc- es, and performed the duties of project engineer for this project. Chuck Hillbery, assistant manager of engineering, and Boyd Rankin, manager of engineering, also contributed to this project. Delbert Davis and Terry Clark managed the construction aspect of the project. For more information, visit www.indres.com. The new truss was installed safely with minimal disruption to production activities. The completed project is ready for another 30 years.