Coal Age Magazine - For more than 100 years, Coal Age has been the magazine that readers can trust for guidance and insight on this important industry.

Issue link: https://coal.epubxp.com/i/1066352

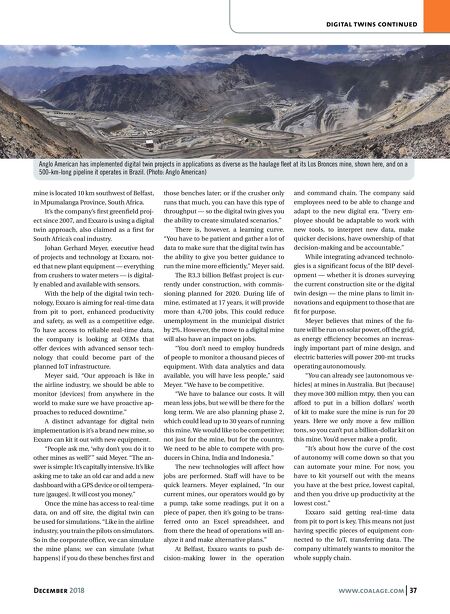

December 2018 www.coalage.com 37 digital twins continued mine is located 10 km southwest of Belfast, in Mpumalanga Province, South Africa. It's the company's first greenfield proj- ect since 2007, and Exxaro is using a digital twin approach, also claimed as a first for South Africa's coal industry. Johan Gerhard Meyer, executive head of projects and technology at Exxaro, not- ed that new plant equipment — everything from crushers to water meters — is digital- ly enabled and available with sensors. With the help of the digital twin tech- nology, Exxaro is aiming for real-time data from pit to port, enhanced productivity and safety, as well as a competitive edge. To have access to reliable real-time data, the company is looking at OEMs that offer devices with advanced sensor tech- nology that could become part of the planned IoT infrastructure. Meyer said, "Our approach is like in the airline industry, we should be able to monitor [devices] from anywhere in the world to make sure we have proactive ap- proaches to reduced downtime." A distinct advantage for digital twin implementation is it's a brand new mine, so Exxaro can kit it out with new equipment. "People ask me, 'why don't you do it to other mines as well?'" said Meyer. "The an- swer is simple: It's capitally intensive. It's like asking me to take an old car and add a new dashboard with a GPS device or oil tempera- ture [gauges]. It will cost you money." Once the mine has access to real-time data, on and off site, the digital twin can be used for simulations. "Like in the airline industry, you train the pilots on simulators. So in the corporate office, we can simulate the mine plans; we can simulate [what happens] if you do these benches first and those benches later; or if the crusher only runs that much, you can have this type of throughput — so the digital twin gives you the ability to create simulated scenarios." There is, however, a learning curve. "You have to be patient and gather a lot of data to make sure that the digital twin has the ability to give you better guidance to run the mine more efficiently," Meyer said. The R3.3 billion Belfast project is cur- rently under construction, with commis- sioning planned for 2020. During life of mine, estimated at 17 years, it will provide more than 4,700 jobs. This could reduce unemployment in the municipal district by 2%. However, the move to a digital mine will also have an impact on jobs. "You don't need to employ hundreds of people to monitor a thousand pieces of equipment. With data analytics and data available, you will have less people," said Meyer. "We have to be competitive. "We have to balance our costs. It will mean less jobs, but we will be there for the long term. We are also planning phase 2, which could lead up to 30 years of running this mine. We would like to be competitive; not just for the mine, but for the country. We need to be able to compete with pro- ducers in China, India and Indonesia." The new technologies will affect how jobs are performed. Staff will have to be quick learners. Meyer explained, "In our current mines, our operators would go by a pump, take some readings, put it on a piece of paper, then it's going to be trans- ferred onto an Excel spreadsheet, and from there the head of operations will an- alyze it and make alternative plans." At Belfast, Exxaro wants to push de- cision-making lower in the operation and command chain. The company said employees need to be able to change and adapt to the new digital era. "Every em- ployee should be adaptable to work with new tools, to interpret new data, make quicker decisions, have ownership of that decision-making and be accountable." While integrating advanced technolo- gies is a significant focus of the BIP devel- opment — whether it is drones surveying the current construction site or the digital twin design — the mine plans to limit in- novations and equipment to those that are fit for purpose. Meyer believes that mines of the fu- ture will be run on solar power, off the grid, as energy efficiency becomes an increas- ingly important part of mine design, and electric batteries will power 200-mt trucks operating autonomously. "You can already see [autonomous ve- hicles] at mines in Australia. But [because] they move 300 million mtpy, then you can afford to put in a billion dollars' worth of kit to make sure the mine is run for 20 years. Here we only move a few million tons, so you can't put a billion-dollar kit on this mine. You'd never make a profit. "It's about how the curve of the cost of autonomy will come down so that you can automate your mine. For now, you have to kit yourself out with the means you have at the best price, lowest capital, and then you drive up productivity at the lowest cost." Exxaro said getting real-time data from pit to port is key. This means not just having specific pieces of equipment con- nected to the IoT, transferring data. The company ultimately wants to monitor the whole supply chain. Anglo American has implemented digital twin projects in applications as diverse as the haulage fleet at its Los Bronces mine, shown here, and on a 500-km-long pipeline it operates in Brazil. (Photo: Anglo American)