Coal Age Magazine - For more than 100 years, Coal Age has been the magazine that readers can trust for guidance and insight on this important industry.

Issue link: https://coal.epubxp.com/i/1066352

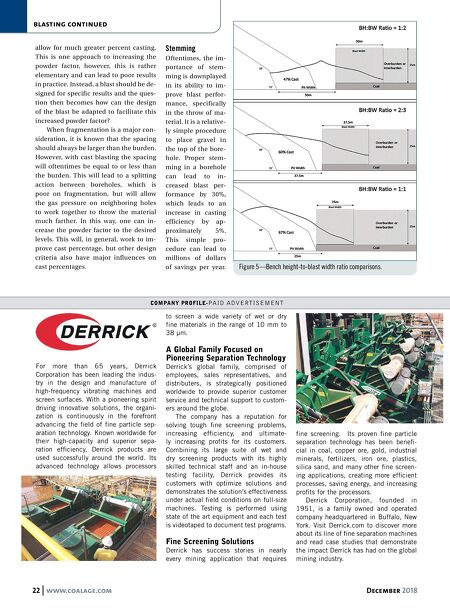

December 2018 www.coalage.com 23 blasting continued A simple way to tell if your stemming is properly functioning is to watch a video and see if any stemming material is being ejected. If the stemming ejects at any point in the duration of the blast, either the stemming is improper, or in most cases, the stemming and/or timing is inadequate. Bench Height-to-Blast Width Ratio Another critical factor is the bench height to face width ratio, which can significantly influence the casting effec- tiveness of a blast. This is another di- rectly controllable variable that will be based on the chosen bench height where the higher the bench, compared to the blast width, the greater the casting effec- tiveness. An example has been presented in Figure 5 where the ratios presented are in the form of (Bench Height-to- Blast Width). It can be seen here that, when a bench height is half the width of the blast width, a 47% cast is achieved, however, when the bench height is equal to the blast width the casting has in- creased to 67% of material in Zone 1. Basically the higher the bench height, the better the cast or the narrower the bench width (less rows) the better the cast. The blast width is typically be set to equal the pit width and once the bench height is at a maximum. The minimum pit width necessary to operate the equip- ment then needs to be determined to op- timize cast. In cast blasting, it is critical www.Derrick.com Derrick ® Stack Sizer ® – high capacity fine screening for wet coal sizing. Reduce Ash Content, Moisture, Dewatering Costs and Eliminate Your Tailings Pond For the past few decades, Derrick ® has successfully commercialized several advance screening technologies in the coal industry. Current state of the art fine screening technology is achieving high efficiency classification as fine as 38 microns. As a result, the company has helped numerous processors in the US and elsewhere with producing cleaner coal, improving clean coal recovery, lowering coal moisture, decreasing dewatering costs as well as the elimination tailings ponds. Whether your need is desliming, scalping, sizing, dewatering, or the recovery of coal/coke fines from settling ponds, Derrick has a proven solution. D E R R I C K ® U R E T H A N E S C R E E N S ® Figure 6—Casting effectiveness to powder factor based on bench height to pit width.