Coal Age Magazine - For more than 100 years, Coal Age has been the magazine that readers can trust for guidance and insight on this important industry.

Issue link: https://coal.epubxp.com/i/961722

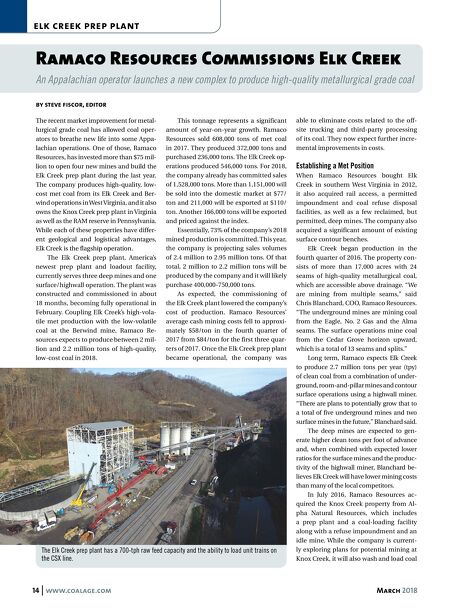

March 2018 www.coalage.com 15 elk creek prep plant continued mined from its Berwind operations there. Berwind is well-positioned on the border of West Virginia and Virginia to fill the anticipated market for low-vol met coals. The Berwind operations are in develop- ment throughout 2018, with production of around 200,000 tpy of clean coal in 2021 and increasing year-over-year. Located in southwestern Pennsylva- nia, the RAM property is scheduled for initial production in 2019. It's expected to produce 500,000 tpy of high-vol met coal from the Pittsburgh No. 8 seam from a room-and-pillar operation. The Pitts- burgh No. 8 seam is often referred to as crossover coal because in can be sold into both steam and met markets. Elk Creek Operations To execute its plans for becoming a low- cost met coal producer, Ramaco Resourc- es knew it had to build a new plant at Elk Creek. "We knew that a modern prepara- tion plant would be required for Elk Creek to reach its full potential," Blanchard said. "Construction activities, however, didn't begin until September 2016." The initial design considerations in- cluded a rail configuration to allow full (150 car) unit train loadings, as well as the ability to recover the maximum amount of fines and to store multiple clean coal products, Blanchard explained. The Elk Creek plant has a raw feed ca- pacity of 700 tons per hour (tph). The plant uses a three-circuit design with a large di- ameter heavy-media cyclone processing coarse coal and spirals and froth flotation recovering the fine coal. "The plant has de- signed with excess fine capacity," Blanchard said. "We oversized the froth flotation circuit and built a large thickener so that we could have longer residence time and higher re- coveries of our fine coal fractions. We also installed Derrick screens to help remove the clays, which also lowers the ash content." Ramaco Resources worked with local contractors to build the plant. Based in Princeton, West Virginia, Raw Resources Group was the general contractor for con- struction. "Even though construction came in behind schedule, we are pleased with the quality of the final construction," Blanchard said. Queen City Railroad Construction in Knoxville, Tennessee, was the general con- tractor for the rail installation. Other major subcontractors included Pineville Paving & Excavating and Tren Services of Pineville, West Virginia and Harts, West Virginia, re- spectively. FLSmidth provided most of the equipment within the preparation plant. Once the Elk Creek contract was signed, first coal ran 13 months later and the plant was fully commissioned in ap- proximately 18 months. "The first coal was processed through the plant on October 28, 2017," Blanchard said. "However, the plant wasn't fully commissioned, fully op- erational including all of the refuse belt systems until February 2018." It is now op- erating at its nameplate capacity. The Berwind mine produces a low-vol met coal. Construction began in September 2016 and the plant was fully commissioned in February 2018.