Coal Age Magazine - For more than 100 years, Coal Age has been the magazine that readers can trust for guidance and insight on this important industry.

Issue link: https://coal.epubxp.com/i/975717

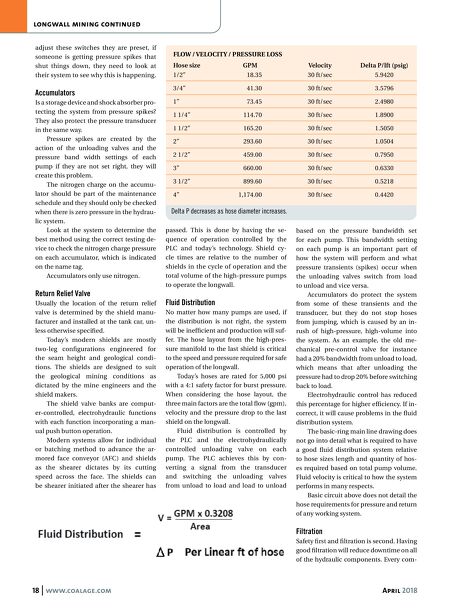

April 2018 www.coalage.com 19 longwall mining continued ponent has a filtration level of cleanliness recommended by the manufacturer. The end user filtration should be equal to or better than the OEM levels. Pressure filters should be no less than 10 microns. Return filters should be no less 7 microns. These filters need to cover the flow re- quirements and have good dirt holding ca- pacities. From a maintenance perspective, they should be located in an easy-change- out position for the filter elements. When running four 100-gpm pumps for 20 hours per day, seven days per week, the filter can see up to 3.36 million gallons of emulsion passing through them a week. Filter element change out should take place once a week. Understanding fluid power system from pumps to filtration will enable long- wall operators to cut coal more safely and efficiently. Alcwyn Elliott is a principal with PATH LLC (Practical Application Hydraulic Training). He has more than 40 years experience train- ing miners on hydraulic systems, including longwall systems. He can be reached at con- sult.my.path@gmail.com. This schematic provides an overview of the entire hydraulic system for a typical longwall. Grasstree Does It Again, Another Longwall Record The Australian-based Grasstree longwall operation, which is part of the Capcoal complex in the Bowen Basin of Central Queensland, has undergone a series of performance upgrades enabling it to deliver world-leading longwall performance resulting in more than 9.3 million metric tons (mt) of coal cut in 2017. Since 2007, Grasstree has used an Eickhoff SL 750 shearer loader to cut its way through the 2.8-m seam at a panel width of 340 m. The high utilization deliv- ered by the shearer averages above 95% and automated operations enable the highest performance while keeping staff out of harm's way. The hard coking coal produced in this operation is mainly used for export and steel manufacturing and transported by rail directly to vessels at the Dalrymple Bay coal terminal. Eickhoff's SL 750 range is fully equipped with advanced automation fea- tures, which enable coal producers to con- tinually break world records on a monthly and annual basis. This machine has proven itself to be a reliable backbone in longwall operations worldwide and is also highly favored by Australian mines. Eickhoff Australia Pty Ltd. is the sales and distribution hub for machines, parts and service in Australia. A new workshop for shearer overhauls is un- der construction in New South Wales and further supporting existing stores and offices for service and parts supply close to the mines in all Australian coal- fields. Currently, Eickhoff Australia is preparing a new SL 750 shearer loader designated to go under- ground at Glencore's Ulan No. 3 mine exchanging an older Eickhoff SL 500 shearer and by that delivering a leap in technology with re- gards to automation functionality, user friendliness and high pro- duction outcomes. The inset award from Eickhoff recognizes Anglo American's Grasstree mine for producing more than 9.3 million mt in 2017 from a single longwall face.