Coal Age Magazine - For more than 100 years, Coal Age has been the magazine that readers can trust for guidance and insight on this important industry.

Issue link: https://coal.epubxp.com/i/987749

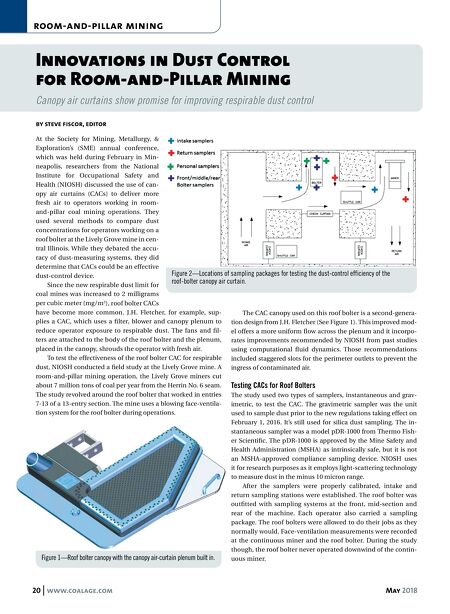

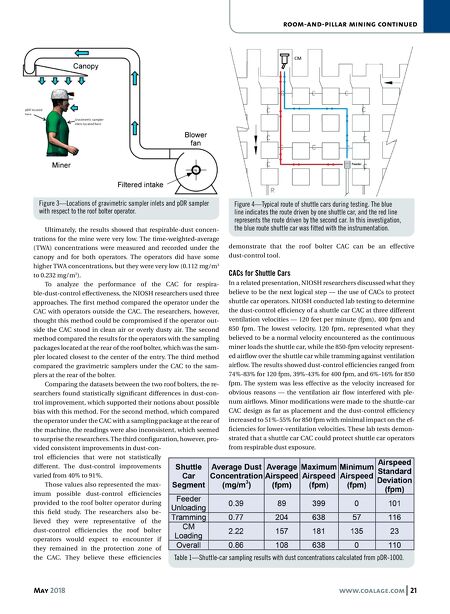

May 2018 www.coalage.com 21 room-and-pillar mining continued Ultimately, the results showed that respirable-dust concen- trations for the mine were very low. The time-weighted-average (TWA) concentrations were measured and recorded under the canopy and for both operators. The operators did have some higher TWA concentrations, but they were very low (0.112 mg/m 3 to 0.232 mg/m 3 ). To analyze the performance of the CAC for respira- ble-dust-control effectiveness, the NIOSH researchers used three approaches. The first method compared the operator under the CAC with operators outside the CAC. The researchers, however, thought this method could be compromised if the operator out- side the CAC stood in clean air or overly dusty air. The second method compared the results for the operators with the sampling packages located at the rear of the roof bolter, which was the sam- pler located closest to the center of the entry. The third method compared the gravimetric samplers under the CAC to the sam- plers at the rear of the bolter. Comparing the datasets between the two roof bolters, the re- searchers found statistically significant differences in dust-con- trol improvement, which supported their notions about possible bias with this method. For the second method, which compared the operator under the CAC with a sampling package at the rear of the machine, the readings were also inconsistent, which seemed to surprise the researchers. The third configuration, however, pro- vided consistent improvements in dust-con- trol efficiencies that were not statistically different. The dust-control improvements varied from 40% to 91%. Those values also represented the max- imum possible dust-control efficiencies provided to the roof bolter operator during this field study. The researchers also be- lieved they were representative of the dust-control efficiencies the roof bolter operators would expect to encounter if they remained in the protection zone of the CAC. They believe these efficiencies demonstrate that the roof bolter CAC can be an effective dust-control tool. CACs for Shuttle Cars In a related presentation, NIOSH researchers discussed what they believe to be the next logical step — the use of CACs to protect shuttle car operators. NIOSH conducted lab testing to determine the dust-control efficiency of a shuttle car CAC at three different ventilation velocities — 120 feet per minute (fpm), 400 fpm and 850 fpm. The lowest velocity, 120 fpm, represented what they believed to be a normal velocity encountered as the continuous miner loads the shuttle car, while the 850-fpm velocity represent- ed airflow over the shuttle car while tramming against ventilation airflow. The results showed dust-control efficiencies ranged from 74%-83% for 120 fpm, 39%-43% for 400 fpm, and 6%-16% for 850 fpm. The system was less effective as the velocity increased for obvious reasons — the ventilation air flow interfered with ple- num airflows. Minor modifications were made to the shuttle-car CAC design as far as placement and the dust-control efficiency increased to 51%-55% for 850 fpm with minimal impact on the ef- ficiencies for lower-ventilation velocities. These lab tests demon- strated that a shuttle car CAC could protect shuttle car operators from respirable dust exposure. Figure 3—Locations of gravimetric sampler inlets and pDR sampler with respect to the roof bolter operator. Figure 4—Typical route of shuttle cars during testing. The blue line indicates the route driven by one shuttle car, and the red line represents the route driven by the second car. In this investigation, the blue route shuttle car was fitted with the instrumentation. Table 1—Shuttle-car sampling results with dust concentrations calculated from pDR-1000.