Coal Age Magazine - For more than 100 years, Coal Age has been the magazine that readers can trust for guidance and insight on this important industry.

Issue link: https://coal.epubxp.com/i/987749

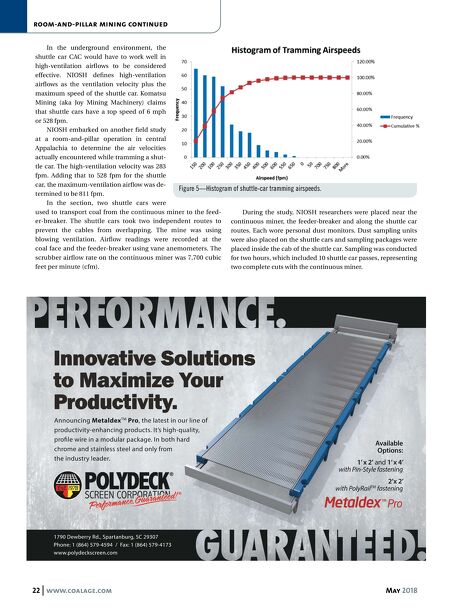

May 2018 www.coalage.com 23 room-and-pillar mining continued The highest-average dust concentrations were observed during the loading process (2.22 mg/m 3 ) and that location had an airflow velocity of 157 fpm. While tramming, the shuttle car operator realized an average concentration of 0.77 mg/m 3 with an average velocity of 204 fpm. The dust levels observed at the feeder-breaker were 0.39 mg/m 3 with a velocity of 89 fpm. The overall TWA dust concentration for the shuttle car was 0.86 mg/m 3 . From the data, the researchers created a histogram (See Figure 5). The shuttle car spent a lot of time sitting idle. When it was tramming, it was doing so in air velocities less than 250 fpm. The researchers found that tramming would be the worst- case scenario for CAC design, but the operator's exposure while tramming was relatively low, averaging 0.77 mg/m 3 . NIOSH said it will use the data collected from the shuttle car air-velocity survey to establish the design parameters to provide a CAC system to better protect shuttle car operators. They also noted that, during this field study, most of the dust exposure for the shuttle car operator occurred while loading coal from the continuous miner, and they thought a CAC system could be designed to drastically reduce the exposure during shuttle car loading would greatly reduce overall shift exposure. It should also be noted that dust exposures occurred during all airspeeds. Most of the airflow speeds encountered by the shuttle car, however, were 450 fpm or less. When evaluating the dust concentrations greater than 1.5 mg/m 3 , the NIOSH researchers noted that most of the airflow speeds encountered were less than or equal to 300 fpm. The amount of high airflow speeds encountered was minimal during this field test, repre- senting 60 seconds out of a total of 6,560 seconds of total tram time. They thought designing a system for these speeds may have minimal impact on the CAC's effectiveness. NIOSH is recommending that subsequent testing be con- ducted at other room-and-pillar operations to gain further insight into the spectrum of air velocities and dust concen- trations that a shuttle car operator experiences to strength- en the design criterion for the CAC. The researchers said they plan to continue laboratory testing of the J.H. Fletcher- designed CAC and provide technical insight about its per- formance and review. Refrerences 1. A Field Study of a Roof Bolter Canopy Air Curtain (2 nd Gen- eration) for Respirable Coal Mine Dust Control, W. Reed, S. Klima, M. Shahan, G. Ross, A. Bailey, K. Singh, R. Cross and T. Grounds; (Preprint 18-003), SME Annual Meeting February 25 - 28, 2018, Minneapolis, Minnesota. 2. Preliminary Laboratory Testing of a Shuttle Car Canopy Air Curtain, W. Reed, Y. Zheng, M. Yekich, G. Ross and A. Salem; SME Annual Meeting February 25-28, 2018, Minneapolis, Minnesota. 3. Field Investigation to Measure Airflow Velocities of a Shuttle Car Using Independent Routes at a Central Appalachian Un- derground Coal Mine, M. Shahan and W. Reed; Dust Control, Ventilation, & Toxic Substances, NIOSH-PMRD, Pittsburgh, Pennsylvania (Preprint 18-032), SME Annual Meeting Feb- ruary 25-28, 2018, Minneapolis, Minnesota. tel: +1-800-691-6601 email: info@strataworldwide.com www. strataworldwide.com Strata AFS TM Advanced Foam Solution Multiple Custom Applications Rock Consolidation, Void Fill & Water Control