Coal Age Magazine - For more than 100 years, Coal Age has been the magazine that readers can trust for guidance and insight on this important industry.

Issue link: https://coal.epubxp.com/i/987749

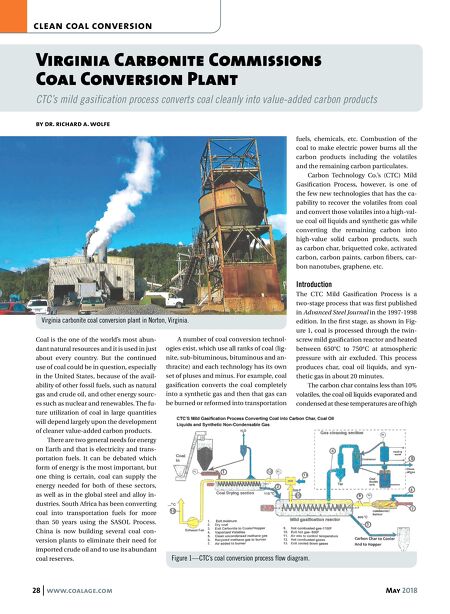

28 www.coalage.com May 2018 clean coal conversion Virginia Carbonite Commissions Coal Conversion Plant CTC's mild gasification process converts coal cleanly into value-added carbon products by dr. richard a. wolfe Coal is the one of the world's most abun- dant natural resources and it is used in just about every country. But the continued use of coal could be in question, especially in the United States, because of the avail- ability of other fossil fuels, such as natural gas and crude oil, and other energy sourc- es such as nuclear and renewables. The fu- ture utilization of coal in large quantities will depend largely upon the development of cleaner value-added carbon products. There are two general needs for energy on Earth and that is electricity and trans- portation fuels. It can be debated which form of energy is the most important, but one thing is certain, coal can supply the energy needed for both of these sectors, as well as in the global steel and alloy in- dustries. South Africa has been converting coal into transportation fuels for more than 50 years using the SASOL Process. China is now building several coal con- version plants to eliminate their need for imported crude oil and to use its abundant coal reserves. A number of coal conversion technol- ogies exist, which use all ranks of coal (lig- nite, sub-bituminous, bituminous and an- thracite) and each technology has its own set of pluses and minus. For example, coal gasification converts the coal completely into a synthetic gas and then that gas can be burned or reformed into transportation fuels, chemicals, etc. Combustion of the coal to make electric power burns all the carbon products including the volatiles and the remaining carbon particulates. Carbon Technology Co.'s (CTC) Mild Gasification Process, however, is one of the few new technologies that has the ca- pability to recover the volatiles from coal and convert those volatiles into a high-val- ue coal oil liquids and synthetic gas while converting the remaining carbon into high-value solid carbon products, such as carbon char, briquetted coke, activated carbon, carbon paints, carbon fibers, car- bon nanotubes, graphene, etc. Introduction The CTC Mild Gasification Process is a two-stage process that was first published in Advanced Steel Journal in the 1997-1998 edition. In the first stage, as shown in Fig- ure 1, coal is processed through the twin- screw mild gasification reactor and heated between 650°C to 750°C at atmospheric pressure with air excluded. This process produces char, coal oil liquids, and syn- thetic gas in about 20 minutes. The carbon char contains less than 10% volatiles, the coal oil liquids evaporated and condensed at these temperatures are of high Virginia carbonite coal conversion plant in Norton, Virginia. Figure 1—CTC's coal conversion process flow diagram.