Coal Age Magazine - For more than 100 years, Coal Age has been the magazine that readers can trust for guidance and insight on this important industry.

Issue link: https://coal.epubxp.com/i/987749

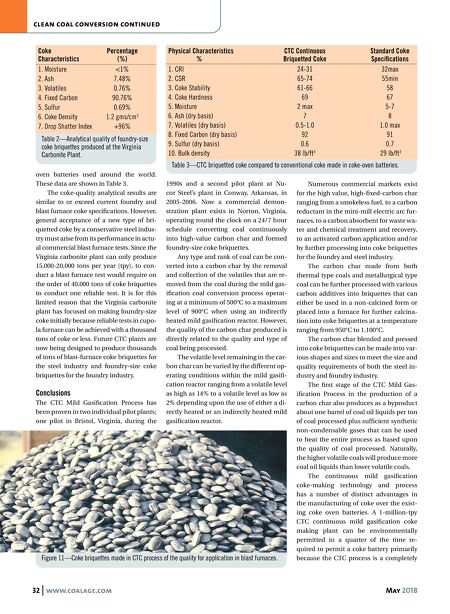

May 2018 www.coalage.com 33 clean coal conversion continued closed loop system with all emissions be- ing collected and scrubbed through one desulfurization emission controlled sys- tem. The cost of that 1-million-tpy CTC plant will be at least two-thirds less than a coke-oven battery coke plant. The oper- ating cost and manpower will be less than one-half the cost of operating a normal coke-oven battery of the same size and the system can be fully automated much like a brick making factory. The calcination of the coke briquettes can be achieved in a tunnel kiln or rotat- ing hearth furnace in less than four hours on a continuous basis rather than the 20-30 hours required in a coke oven bat- tery. A percentage of the coke can be made from using high-quality carbon char made from lower-cost thermal type coals rather than all metallurgical quality coals normally required to make coke in coke oven batteries. The CTC coke briquettes have a num- ber of advantages over conventional coke produced in coke ovens. The briquette's quality is equal or better than convention- al coke. The coke briquettes have about 20% higher density that conventional coke. The coke briquettes have less break- age than conventional coke after shipping. The coke briquettes are all the same size and allows better and more even air flow through both the cupola foundry furnac- es and blast furnaces for melting iron ore. Various size coke briquettes can be made from a 3- x 4-in. briquettes up to 6- x 8- x 5-in. briquettes typical desired by the foundry industry. The CTC carbon-char process re- moves the volatiles from the coal that are condensed into valuable coal oil liquids and synthetic non-condensable gases. The coal oil liquids have a commercial value to the refining industry at a price of about 15%-20% higher than crude oil prices. The quantity of synthetic non-condensable gases is sufficient in heat value to provide the heat source for the entire CTC mild gasification process. Dr. Richard A. Wolfe is president and man- aging director of the Carbon Technology Co. LLC, located in Bristol, Virginia. He can be reached at rwolfe@skybest.com. In 2013, Dr. Wolfe assigned his two patents to Nucor Corp. In September 2014, the Wolfe's sold their intellectual property rights as they pertained to the Virginia Carbonite Plant to Fuel Tech Inc., and received in return, a royalty-free operating license to the Virgin- ia Carbonite LLC whom is currently operat- ing the Virginia Carbonite Plant in Norton, Virginia. References 1. The CTC continuous coke making process was published, Advanced Steel Journal, 1997-1998, Crambeth Allen Publishing, Hopesay, Craven Arms SY7 8HD, U.K. 2. Patent No. 8,444,823 entitled "Pyro- lyzer Furnace Apparatus and Method for Operation Thereof," dated May 21, 2013. 3. Patent No. 9,045,693 entitled "Pyro- lyzer Furnace Apparatus and Method of Operation Thereof, Titled B," dated June 2, 2015. For more information CONTACT US for NO cost, NO obligation testing www.somersetenvironmental.com 724-591-8481 The best aeration system on the market, GUARANTEED! » No moving parts . » Indestructible HDPE plastic. » Can be built to any size flow. » Least expensive. » Most cost efficient. ACID MINE WASTEWATER TREATMENT SYSTEM MAELSTROM OXIDIZER ™ 0 $ CONTACT US for NO cost, NO obligation testing www.somersetenvironmental.com 724-591-8481 $AVE THOUSANDS ON YOUR ACID MINE WASTEWATER TREATMENT (typical savings > 70%) 0 OUT OF POCKET 0 IF YOU DON'T SAVE YOU DON'T PAY!