Coal Age Magazine - For more than 100 years, Coal Age has been the magazine that readers can trust for guidance and insight on this important industry.

Issue link: https://coal.epubxp.com/i/1055558

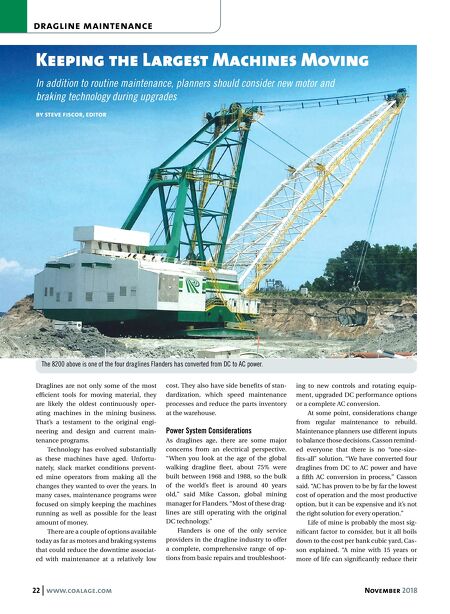

22 www.coalage.com November 2018 dragline maintenance Draglines are not only some of the most efficient tools for moving material, they are likely the oldest continuously oper- ating machines in the mining business. That's a testament to the original engi- neering and design and current main- tenance programs. Technology has evolved substantially as these machines have aged. Unfortu- nately, slack market conditions prevent- ed mine operators from making all the changes they wanted to over the years. In many cases, maintenance programs were focused on simply keeping the machines running as well as possible for the least amount of money. There are a couple of options available today as far as motors and braking systems that could reduce the downtime associat- ed with maintenance at a relatively low cost. They also have side benefits of stan- dardization, which speed maintenance processes and reduce the parts inventory at the warehouse. Power System Considerations As draglines age, there are some major concerns from an electrical perspective. "When you look at the age of the global walking dragline fleet, about 75% were built between 1968 and 1988, so the bulk of the world's fleet is around 40 years old," said Mike Casson, global mining manager for Flanders. "Most of these drag- lines are still operating with the original DC technology." Flanders is one of the only service providers in the dragline industry to offer a complete, comprehensive range of op- tions from basic repairs and troubleshoot- ing to new controls and rotating equip- ment, upgraded DC performance options or a complete AC conversion. At some point, considerations change from regular maintenance to rebuild. Maintenance planners use different inputs to balance those decisions. Casson remind- ed everyone that there is no "one-size- fits-all" solution. "We have converted four draglines from DC to AC power and have a fifth AC conversion in process," Casson said. "AC has proven to be by far the lowest cost of operation and the most productive option, but it can be expensive and it's not the right solution for every operation." Life of mine is probably the most sig- nificant factor to consider, but it all boils down to the cost per bank cubic yard, Cas- son explained. "A mine with 15 years or more of life can significantly reduce their The 8200 above is one of the four draglines Flanders has converted from DC to AC power. Keeping the Largest Machines Moving In addition to routine maintenance, planners should consider new motor and braking technology during upgrades by steve fiscor, editor