Coal Age Magazine - For more than 100 years, Coal Age has been the magazine that readers can trust for guidance and insight on this important industry.

Issue link: https://coal.epubxp.com/i/1055558

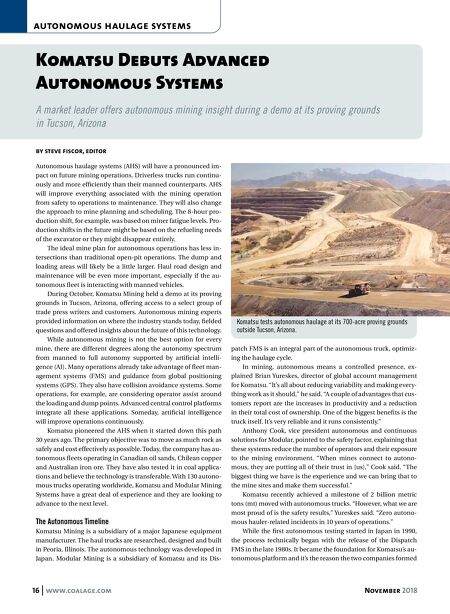

16 www.coalage.com November 2018 autonomous haulage systems Komatsu Debuts Advanced Autonomous Systems A market leader offers autonomous mining insight during a demo at its proving grounds in Tucson, Arizona by steve fiscor, editor Autonomous haulage systems (AHS) will have a pronounced im- pact on future mining operations. Driverless trucks run continu- ously and more efficiently than their manned counterparts. AHS will improve everything associated with the mining operation from safety to operations to maintenance. They will also change the approach to mine planning and scheduling. The 8-hour pro- duction shift, for example, was based on miner fatigue levels. Pro- duction shifts in the future might be based on the refueling needs of the excavator or they might disappear entirely. The ideal mine plan for autonomous operations has less in- tersections than traditional open-pit operations. The dump and loading areas will likely be a little larger. Haul road design and maintenance will be even more important, especially if the au- tonomous fleet is interacting with manned vehicles. During October, Komatsu Mining held a demo at its proving grounds in Tucson, Arizona, offering access to a select group of trade press writers and customers. Autonomous mining experts provided information on where the industry stands today, fielded questions and offered insights about the future of this technology. While autonomous mining is not the best option for every mine, there are different degrees along the autonomy spectrum from manned to full autonomy supported by artificial intelli- gence (AI). Many operations already take advantage of fleet man- agement systems (FMS) and guidance from global positioning systems (GPS). They also have collision avoidance systems. Some operations, for example, are considering operator assist around the loading and dump points. Advanced central control platforms integrate all these applications. Someday, artificial intelligence will improve operations continuously. Komatsu pioneered the AHS when it started down this path 30 years ago. The primary objective was to move as much rock as safely and cost effectively as possible. Today, the company has au- tonomous fleets operating in Canadian oil sands, Chilean copper and Australian iron ore. They have also tested it in coal applica- tions and believe the technology is transferable. With 130 autono- mous trucks operating worldwide, Komatsu and Modular Mining Systems have a great deal of experience and they are looking to advance to the next level. The Autonomous Timeline Komatsu Mining is a subsidiary of a major Japanese equipment manufacturer. The haul trucks are researched, designed and built in Peoria, Illinois. The autonomous technology was developed in Japan. Modular Mining is a subsidiary of Komatsu and its Dis- patch FMS is an integral part of the autonomous truck, optimiz- ing the haulage cycle. In mining, autonomous means a controlled presence, ex- plained Brian Yureskes, director of global account management for Komatsu. "It's all about reducing variability and making every- thing work as it should," he said. "A couple of advantages that cus- tomers report are the increases in productivity and a reduction in their total cost of ownership. One of the biggest benefits is the truck itself. It's very reliable and it runs consistently." Anthony Cook, vice president autonomous and continuous solutions for Modular, pointed to the safety factor, explaining that these systems reduce the number of operators and their exposure to the mining environment. "When mines connect to autono- mous, they are putting all of their trust in [us]," Cook said. "The biggest thing we have is the experience and we can bring that to the mine sites and make them successful." Komatsu recently achieved a milestone of 2 billion metric tons (mt) moved with autonomous trucks. "However, what we are most proud of is the safety results," Yureskes said. "Zero autono- mous hauler-related incidents in 10 years of operations." While the first autonomous testing started in Japan in 1990, the process technically began with the release of the Dispatch FMS in the late 1980s. It became the foundation for Komatsu's au- tonomous platform and it's the reason the two companies formed Komatsu tests autonomous haulage at its 700-acre proving grounds outside Tucson, Arizona.